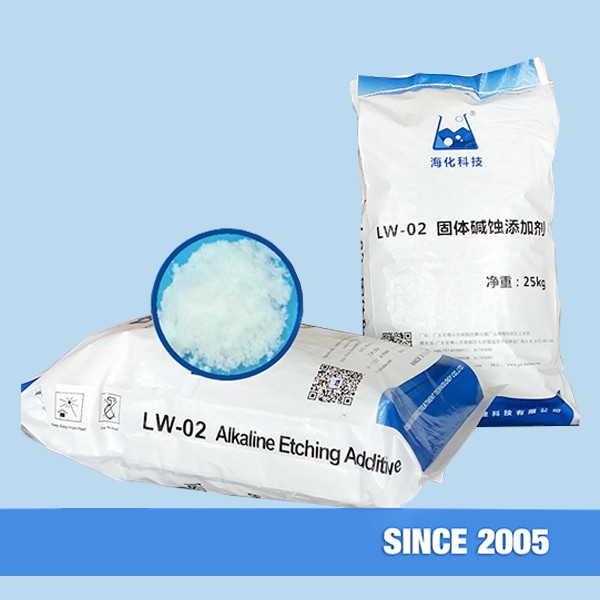

Alkaline Etching Additive(Solid)

LW-02 Alkaline Etching Additive is a white to light yellow solid powder. It is used for avoiding the scale formation and the aluminium dissolution can be over 120g/L. The additive can improve the aluminium profile surface quality, decrease the aluminum loss and the consumption of alkali. It is eco-friendly.

1. Bath Make-up:

Name | Quantity | Unit |

LW-02 | 7 | g/L |

Sodium Hydroxide (NaOH) | 40 | g/L |

Water | Balance | |

2. Operating Conditions:

Name | Quantity | Unit |

Temperature | 40-65 | ℃ |

Time | 1-25 | min |

Free alkali (Sodium Hydroxide) | 40-70 | g/L |

3. Solution Maintenance:

1) Analyze the concentration of free alkali and aluminum ion everyday. It is recommended that the concentration of free alkali in a new make-up bath should be 40g/L. And the alkali concentration and solution temperature are slowly increased according to the increasing of aluminum ion. LW-02 and alkali should be added with the scale of 1/10-1/6.

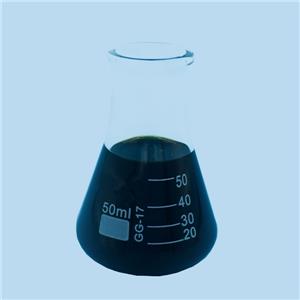

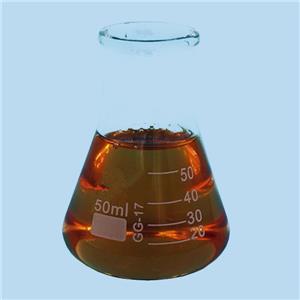

2) Normally, the color of the solution is dark-gray. It will be light-grey if it lacks of alkali or LW-02, then need to replenish in time.

3) When the etching solution is not being used, may increase the concentration of sodium hydroxide (NaOH) and LW-02 for avoiding precipitations.

4. Packaging and Storage:

Package: Carton (30kg/ carton,25kg/bag)

Storage: Suggested to store in a cool, dry and well ventilated place; away from fire and heat source.

5.Introduction to Alkaline Etching Additive(Solid)

Alkaline Etching Additive(Solid) are chemical agents used in metal surface treatment, primarily available in solid form. They are often composed of strong alkaline compounds such as sodium hydroxide (NaOH) or potassium hydroxide (KOH). These chemicals react with metal surfaces to remove oxides, grease, and other contaminants, thereby improving the surface condition of the metal and preparing it for subsequent processes like coating, plating, or bonding. Alkaline Etching Additive(Solid) are valued in industrial metal processing for their effectiveness in cleaning and surface preparation.

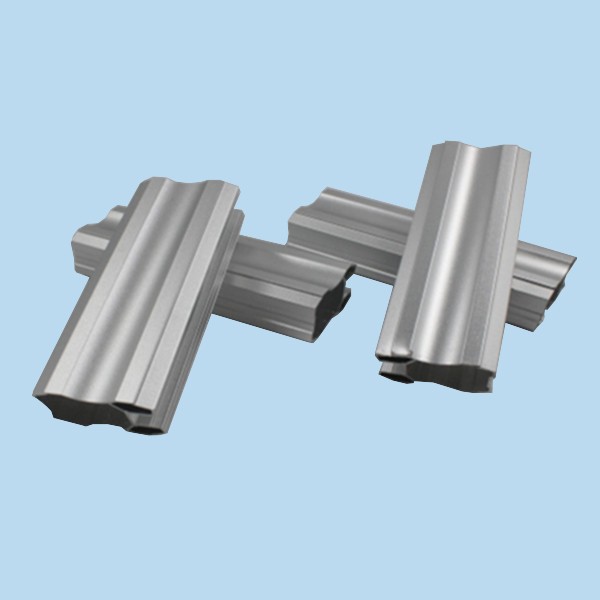

6.Applications of Alkaline Etching Additive(Solid) in Aluminum Processing

**Oxide Layer Removal**

- Aluminum naturally forms a dense oxide layer (Al₂O₃) when exposed to air, which protects it from further oxidation. However, this oxide layer may need to be removed during certain processing steps. Alkaline Etching Additive(Solid) are effective in dissolving and removing this oxide layer, restoring the aluminum surface's activity and ensuring a clean, unobstructed surface for subsequent processes like coating or plating.

**Surface Cleaning**

- During the manufacturing and storage of aluminum, the surface can become contaminated with oils, dust, or other pollutants. Alkaline Etching Additive(Solid) are used to thoroughly clean these contaminants from the aluminum surface, leaving it clean and ready for further processing, such as welding, bonding, or coating.

**Etching Process**

- When specific textures or patterns are needed on the aluminum surface, etching is a key process. Alkaline Etching Additive(Solid) are used to uniformly etch the aluminum surface by carefully controlling the solution's concentration, temperature, and treatment time, thereby creating the desired textures. This process is widely used in the production of aesthetically appealing aluminum products like electronic device housings and architectural decorative materials.

**Surface Pre-treatment Before Welding or Bonding**

- The cleanliness and activity of the surface are crucial when welding or bonding aluminum.Alkaline Etching Additive(Solid) effectively remove oxide layers and impurities, enhancing surface activity and improving the quality and strength of the weld or bond. Improper pre-treatment can lead to weak bonds or poor weld quality, impacting the product's durability and performance.

**Pre-treatment Before Electroplating**

- Electroplating requires a substrate with good adhesion properties. Before electroplating, aluminum typically undergoes treatment with Alkaline Etching Additive(Solid) to remove oxide layers and slightly roughen the surface. This improves the adhesion and uniformity of the plating, ensuring the durability and appearance of the electroplated layer.

**Process Control**

- During aluminum processing, precise control of the solution concentration, temperature, and treatment time is essential when using Alkaline Etching Additive(Solid) . This control prevents over-etching or surface damage, which is crucial for ensuring the effectiveness of the treatment and the quality of the final product.